JP / EN

Laser system

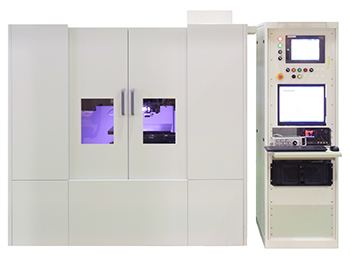

Ultra short pulse laser processing system

It's a high-quality laser processing system using a femtosecond laser.

We have achieved high-precision and high-quality machining of metals, ceramics, glass, and silicon without thermal effects and without burrs or dross.

Ultra short pulse laser processing system

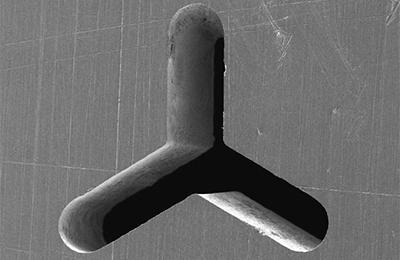

It‘s combining an ultra-short pulse laser and an ultra-high-speed multi-axis control galvano scanner. It's a system that achieves high-precision and high-quality machining of metal, ceramics, glass, and silicon without being affected by heat. From the SEM photograph, this processing is high quality processing without burr and dross. This system can make 25μm diameter straight hole without taper. It is also possible to control the taper angle for reverse taper or normal taper processing. This system is capable of drilling holes of any shape by combining the multi-axis galvano scanner and X-Y work stage.

We also accept sample test processing, and we will also consult on behalf of processing.

We also accept sample test processing, and we will also consult on behalf of processing.

| Ultra short pulse laser processing system | |

| Laser | Ultra short pulse high power femtosecond laser (Green or IR) |

| Maximum work size | 500mm x 500mm |

| Minimum hole size | 25μm |

| Hole form | Reverse taper, positive taper, straight hole processing |

| Aspect ratio | About 10 times |

| Surface roughness | Ra 0.1 μm or less |

| Material | All metals, ceramics, silicon, glass, SiC, resin films, etc. |

| System size | ---- |

| Utility | ---- |

Processing example

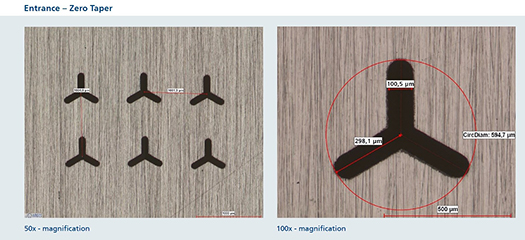

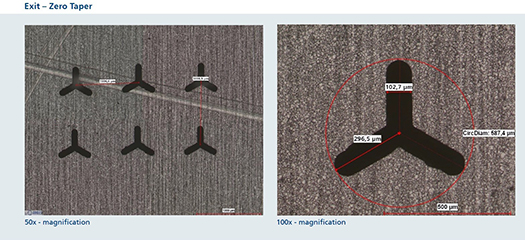

This is a photograph of a variant hole machined in metal with an ultrashort pulse laser system. The two on the left are the images on the laser incident side, and the two on the right are the images on the laser emitting side. The outer diameter is 594.7 μm on the entrance side and 587.4 μm on the exit side. Even if the processing size exceeds 500 μm, the difference is only 7.3 μm. The size difference ratio between the entrance side and the exit side is 98.8%.You will find that straight hole processing is achieved even with such irregular shapes.The quality around the hole is also very high.

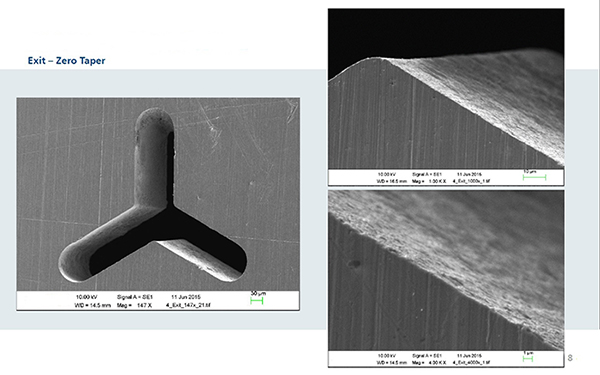

SEM photograph on the left, it's make a variant hole using the that system. The side wall of the hole is also very smooth.

No burrs or chips are observed even in the enlarged SEM photograph,proven to be processed to high quality.

This system combines ultra-short pulse laser and ultra-high-speed multi-axis control galvano scanner for extremely high quality micro-machining.